Join JPI UE

Faq

FAQ

Please click here for the frequently asked questions we collected.

If you have an additional questions you are welcome to mail us at info@jpi-urbaneurope.eu

“Cities are accumulators of vast amounts of resources and producers of high volumes of waste,” states Foundries of the Future. The economics of a linear ‘take, make, waste’ manufacturing model have led to the exploitation of raw materials, obliterating ecosystems and ejecting masses of greenhouse gasses.

Waste management, as the Cities Report points out, offers a solution for how we “produce and use goods in ways which do not create harm for current or future generations”. But is it really the right way to go? How can we repurpose by-products? And what else do we have to gain from it?

Why Care About Waste?

Much of Europe’s unwanted industrial junk is shipped off to countries like Bangladesh, Mexico, and the Philippines, where it is mostly burned, buried, or thrown into nature. For the West, it’s out of sight, out of mind. But in reality, it’s an ecological disaster and gross exploitation of developing economies.

Reusing waste helps to correct this inequality. The promise of extracting value from waste on home turf can be leveraged as an incentive. Cutting the need to manage waste, so estimates the World Bank, can save up to 20% of municipal budgets.

Seeing waste as a material allows us to trace exactly where resources come from and manage their ecological impact. By creating a circular economy, cities benefit financially many times over from a single material. It stimulates a job market by incubating innovation and creating low-barrier roles for people willing to sort the detritus.

Forms of Useful Waste

Don’t limit a vision. Waste is plastic, cardboard, wood, ceramics, or material offcuts from clothing. It is microchips, construction and demolition (C&D) waste, and greywater. Almost any material can be a resource and viewing it as such leads to new business opportunities, especially inventive and eco-friendly start-ups.

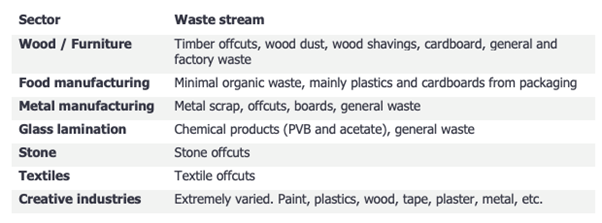

Manufacturing sectors and their reusable waste products. Image credit: Cities of Making / OPDC Report

Densification of urban areas creates new synergies. It may seem unlikely, but energy is a reusable waste product. The warmth emitted from a butcher’s freezer, for example, now heats an aquaculture farm on a neighbouring rooftop in the Abattoir district of Brussels.

Like repairs, food, drink, and building materials are all considered staples of contemporary urban manufacturing. Rich in yeast, a London-based bread specialist sells unsold leftovers to local brewers. In Haringey, unwanted bread gets collected to make high-quality animal feed. There are also companies compacting food waste into sustainable building materials. Again in London, used coffee grounds collected from cafés are used to make biofuels while in Rotterdam they feed mushroom farms.

Why Not Recycle?

Sometimes, waste is unavoidable. At others, it is a consequence of our throwaway culture. Despite having potable water on tap, we insist on drinking from plastic bottles. Finding ways to make use of waste is important, but first we should attempt to minimise the volume of rubbish we generate with intelligent product design.

Excluding this, four options are available before we consider reusing waste. Collectively, they make up the circular economy.

The most popular and widely practiced intervention is recycling. This is expensive – especially for furniture and electronics – uses horrendous amounts of energy in processing and transportation, and cannot be applied to all materials.

We should first consider the options that eliminate planned obsolescence and decrease a city’s long-term waste management costs. The UK‘s Right to Repair law, for example, makes it compulsory for manufacturers to produce spare parts, hoping to increase the rate of repairs. Offering this service can diversify income streams for skilled tradespeople.

Other Barriers

Cities of Making identifies limitations “for urban areas to capture and sort waste resources”. Manufacturers are hard-pressed to create waste material flows without the support of a city’s designers, engineers, and decision-makers. Using residual heat or greywater requires comprehensive infrastructure. Segregating materials for processing and reuse is timely and expensive. Access to deposit and collection points may be limited where priority for land use is given over to housing and soft mobility.

Making from waste requires an overhaul at a policy level. Cities of Making notes: “The legal and institutional framework around waste can mean that usable resources or potentially valuable waste streams are not recovered due to the administrative restrictions imposed on the movement and exchange of waste.”

A Wasteful Resource in Practice

The London Plan proves the capital’s seriousness around making approximately 56 million tonnes of material waste useful to manufacturers annually. It includes “a commitment to generate low carbon energy from waste”, protection for “existing waste management sites”, and identifying “suitable locations for managing waste” in the form of Strategic Industrial Locations (SILs). These are examples other cities can duplicate. Rotterdam and Brussels have similar plans to implement robust circularity systems.

High-value recovery is proven to be so beneficial that enterprising manufacturers or areas of the city are capitalising on it by becoming net importers of waste. Old Oak and Park Royal has introduced a “waste transfer station, metal reclamation and C&D waste treatment” to process the materials they bring in from elsewhere and create jobs in waste management.

Steps to Take

A coordinated effort between city authorities and manufacturers is needed to create a ‘waste as a resource’ culture.

Making from Waste in a Nutshell

Manufacturing new products from old waste creates a more resilient urban economy and reduces the ecological and social damage the sector causes. Almost any by-product can be reused if the relevant processes and infrastructure are in place. For this to work, it’s up to cities and makers to work together, be transparent and accountable, and embrace a whole new culture. But first, stop and think: how can we manufacture goods to minimise waste overall? As beneficial as it is, reuse and recycling should still be a last resort.